STEM High Pressure Reaction Station Heating Blocks

from Thermo Fisher Scientific

ATS10007 ATS10180 ATS10227 PS10000 RA1501X1 RA1501X2

ATS10007 ATS10180 ATS10227 PS10000 RA1501X1 RA1501X2

Discontinued

Designed for High Pressure Reactions

- Perform 10 high-pressure chemical reactions on a bench-scale operation.

- Small volume vessels (1-25 ml).

- Precise temperature control with rapid heating and cooling.

- Easy access into the reaction vessel.

- Fast and easy set-up.

Product Description

- The Reaction Blocks can be controlled over the complete temperature range from -30°C to +150°C.

- The maximum temperature difference between any two positions or zones is 180°C with zero cross talk.

- Control heating and cooling ramp rates from 0.1 to 5°C/minute.

Safety

- The well-insulated heat block keeps the casework cool-to-the-touch.

- Thermal cutout eliminates runaway conditions.

- Designed to withstand pressures well in excess of 2000 psi, with an Integral Safety Rupture Disc to protect the vessel and operator from dangerous pressures beyond the rated limit for the vessel.

- Vessels comply with ASME Code Section VIII, Division 1.

Operation

- Simple to use software - allows you to control temperature and stirring.

- Scheduling a new or editing an existing protocol is made fast and easy with the software.

- Protocols can be changed while the reactions are running.

- Real time values are available if so desired.

- Multiple chemists can use the same unit simultaneously.

- Soft Start feature reduces sample fragmentation.

- If the motor stalls or jams, power is removed from the motor and a “motor-jammed” message is reported back to the controlling system.

- Monitor changes in the viscosity of your solution - through its use, a “viscosity” value is reported.

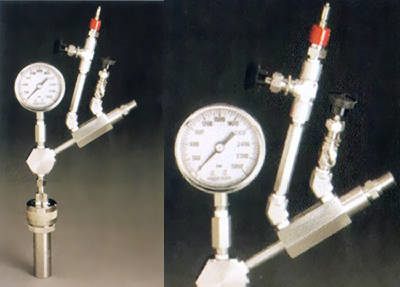

Product Description for Reaction Vessels

- Designed for pressure up to 2000 psi, the High Pressure Reaction Vessels has a working volume of 1 to 25 ml.

- Each Reaction Vessel contains:

- - Analog Pressure Gage will display the pressure within each vessel at all times.

- - Liquid Sampling Valve is used for withdrawing liquid samples through the dip tube shared with the gas inlet valve.

- - Incoming gas can be sued to clear the dip tube between liquid samples.

- - Gas Release Valve is used to release gas from the reactor during or at the completion of a run.

- - Safety Rupture Disc has been designed to protect the vessel and the operator from dangerous pressures beyond the rated limit for the vessel.

- - Gas Inlet Valve has been designed for charging gas into the reactor.

- - This valve and the liquid sampling valve are connected to a dip tube, which extends to the bottom of the vessel.

- - Customization is available. customization can be provided at an additional cost -- special alloy construction of the vessels, external valves, fittings, gage and rupture disc all can be changed.