Thermo Scientific Forma Stackable Shakers

from Thermo Fisher Scientific

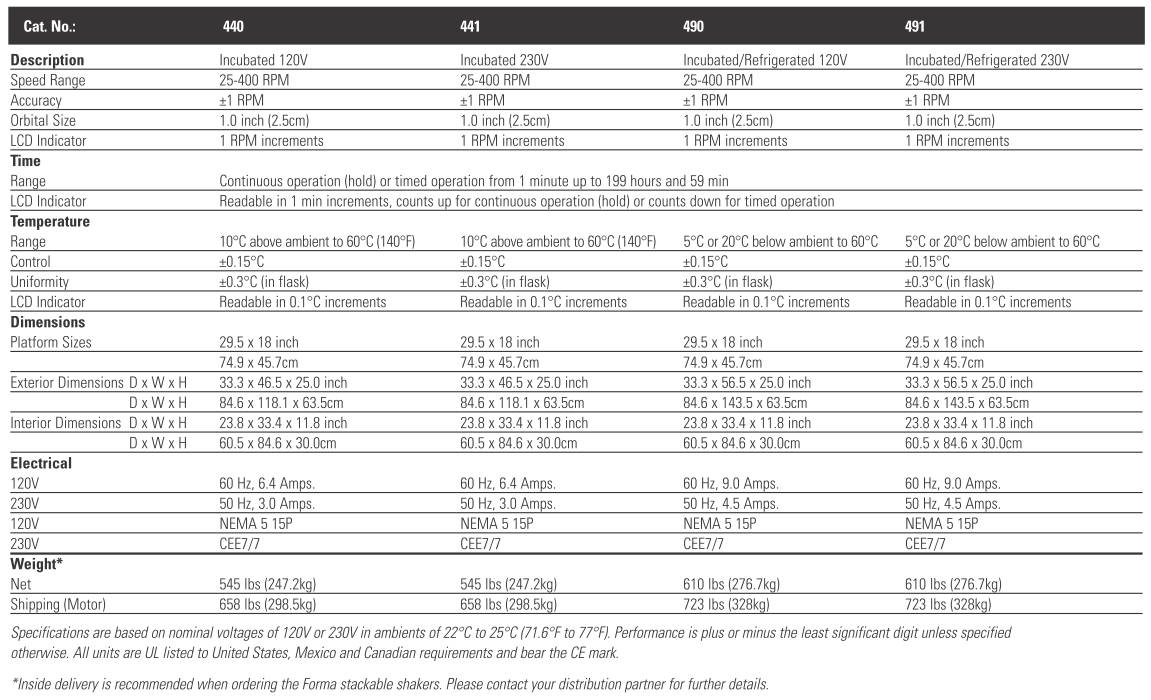

440 441 490 491

440 441 490 491

Discontinued

- Recommended Substitute: Thermo Scientific* MaxQ 8000 Incubated & Refrigerated Stackable Shakers.

Maximized shaker capacity for space restricted labs.

- Our Forma Stackable Shaker product line includes stackable models in both refrigerated and incubated configurations.

- Incubated Model 440 (441) and Refrigerated Model 490 (491) are specially designed for laboratory professionals seeking high capacity shakers but lacking the floor space to accommodate multiple large floor models.

- All models feature an insulated, fold-down door with wide-view window for high visibility.

- Robust, functional, convenient and unique design.

Product Description.

- Electronic components and HEPA filter are easily accessed from the front of the unit, eliminating the need to move the shaker during regular maintenance or service. HEPA filter ensures that air inside the unit remains clean and reduces cross contamination so culturing conditions are improved.

- Fold-down door with ergonomically designed door handle, large quick-release base (included), and dedicated or universal slide-out shaker platform provide convenient access to your product, regardless of its position on the 29.5" x 18" (74.9cm x 45.7cm) platform. Universal and dedicated platforms are ordered separately.

- Flip-down handle/latch on the quick-release base prevents the shaker from running if the universal or dedicated platform is not secured.

- Easy-to-clean platforms are constructed of 5 /16", heavy-duty, brushed anodized aluminum, which does not chip or rust.

- Heavy-gauge cold-rolled steel exterior is designed to safely support units stacked three high.

- Top platform height is under 61.0" (154.9cm) when units are stacked three high, ensuring ease-of-use and convenient accessibility.

- Crevice-free Type 304 stainless steel chamber with coved corners and built-in drain keeps spills within the work area and promotes easy cleaning. Chamber is tall enough to hold 2 liter Erlenmeyer flasks.

- Chamber xenon light with switch improves visibility.

- Shaker door features a magnetic gasket for a tight seal, pneumatic dampers for smooth controlled opening, and hinges with counterbalance springs to ease door closing.

- World’s most durable and dynamically balanced orbital shaker mechanism ensures smooth operation for optimum oxygenation and nutrient mixing, reduced cell clumping, and prevention of splashing and flask wetting.

- Triple counterbalanced mechanism provides optimum handling of full or unbalanced loads, regardless of flask placement.

- Heavy-duty, eccentric drive mechanism allows extended speed ranges from 25 to 400 RPM, ±1 RPM with minimal vibration, even when shakers are stacked three-high.

- Slide-out platform features a large mounting surface area and is secured to ensure a smooth, stable motion. Platform motion is continuously monitored independently of motor operation for added protection.

- Heavy-duty, permanently lubricated bearings provide long life. Cool running, brushless, 1 /3 HP, DC motor ensures continuous maintenance-free operation.

- Airflow: Forced air circulation system and built-in High Efficiency Particulate Air (HEPA) filter for temperature uniformity and reduced risk of cross contamination make these shakers ideal for eukaryotic cell culture. HEPA filter is rated a minimum 95% efficient at 0.3 microns for entrapment of extraneous airborne particulates.

- All microprocessor functions can be calibrated easily through the keypad. Sealed control panel minimizes concern about accidental spills.

- Audio/visual, high/low RPM tracking alarms alert you if speed deviations occur. Alarms can be silenced temporarily and ring back as a reminder of unresolved alarm conditions.

- Non-volatile memory saves settings during a power outage and automatically restarts the unit after power is restored.

- Microprocessor tracks total accumulated time on motor and drive systems.

- Controlled acceleration circuitry provides smooth start-up and stopping to eliminate splashing and wetting of flask closures.

- RS232 port is standard and permits computer interface and monitoring of time, temperature and speed.

- For long-term documentation an optional free standing chart recorder is available.

- Standard remote alarm contacts allow convenient monitoring of alarm conditions from another location.

Microprocessor Control/Monitoring System for easy use.

- Run points and Set points are displayed simultaneously.

- Audio/Visual Alarm Indicator: Audio/visual over and undertemperature tracking alarms ensure product protection. A separate adjustable overtemperature safety alarm with independent probe provides additional backup on heated units. Refrigerated units also feature an under-temperature safety alarm.

- Backlit Display: Two-line, 40 character, LCD, alphanumeric display is a complete message/information center for actual (run) and setpoint parameters, and alarm condition messages. Provides message visibility in low and bright light conditions.

- Up and Down Arrow Keys : During programming, these keys increase and decrease the time, speed, and temperature values.

- Start: Starts the shaker’s operation.

- Alarm Silence.

- Run points and Set points: Both are displayed simultaneously.

- Time, Speed, and Temp C: Icons/buttons allow easy programming of set parameters.

- - Time: Counts upward, showing total operating hours and minutes for the run.

- - Speed: Displays the actual platform speed (RPM).

- - Temp C: Displays the actual temperature inside the chamber.

- Stop: Causes the shaker to stop operating.