Thermolyne Temperature Furnace Control Information

from Barnstead International

Temperature Control: Precision and Accuracy

- The temperature control system in Barnstead Thermolyne furnaces consists of four major components: controller, power-switching device, heating elements, and a thermocouple sensor (Figure 1).

- All of the Barnstead Thermolyne furnace control systems are closed-loop for accuracy and safety.

- In a closed-loop system, the temperature sensed by the thermocouple gives a feedback signal to the controller that in turn regulates power to the heating elements by means of the switching device.

- The selection of components within the control loop for a particular furnace model is largely based on the desired operating temperature range and the magnitude of overall temperature error that is acceptable within that range.

- The overall error is defined as the difference between the set value and the actual value of the furnace chamber or load.

- The overall error is broken down into the precision of the temperature reading and its accuracy.

- Temperature precision is largely determined by the controller.

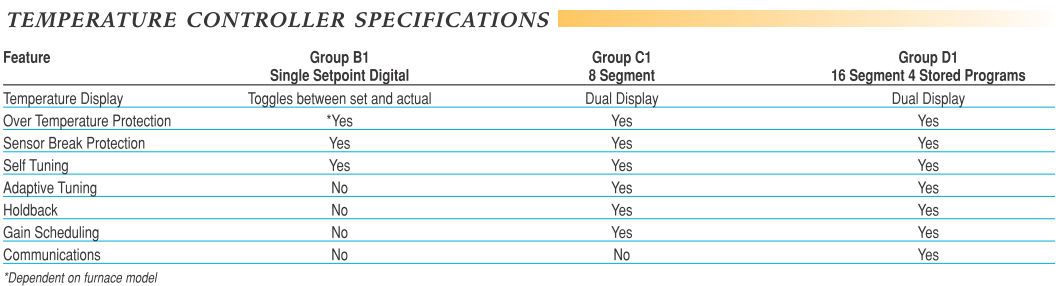

- Our economy solid tube furnaces use analog controllers and all other Barnstead Thermolyne furnaces utilize microprocessor (digital) three-term controllers (Proportional + Integral + Derivative or PID).

- PID control is very precise in that small fluctuations in chamber temperature are quickly adjusted to maintain the set temperature.

- In addition, the PID type controller reaches the desired chamber temperature and reduces the chance of overshooting the value.

- This is particularly important to consider if the furnace workload is sensitive to temperatures slightly above the setpoint.

- Temperature control in furnaces is the most precise above 260°C.

- Other factors to consider with regard to accuracy include the size and density of the material being heated and the thermal lag of the material relative to the chamber temperature.

- Large, dense materials will obviously require more time to reach the set temperature.

Over-Temperature Protection (OTP)

- Digital controllers are designed with two types of OTP.

- A "full-scale high" alarm will be in effect when the furnace chamber exceeds its maximum allowable temperature.

- The controller will cut power to the heating elements until the chamber cools to a value below this limit.

- This value is defined by the heating capacity of the elements, the thermocouple, and the insulation and cannot be modified by the operator.

- The second type of OTP, the "deviation high" alarm is designed to protect the furnace workload and can be changed by the operator.

- We recommend setting this value to 20°C above the working temperature of the load.

Sensor Break Protection

- All Barnstead Thermolyne controllers provide for a safe response should there be a loss of input signal because of a broken thermocouple or an open circuit.

- Power to the heating elements is terminated and a message flashes on the display.

Tuning

- The digital controllers can be automatically tuned to improve product or process quality.

- Self-tuning is a built-in software package for automatically determining the PID and other control parameter values.

- For maximum performance, this feature should be used the first time the furnace is used and each time the setpoint or the type of load is changed.

Programming

- Many processes require the temperature to vary according to a precise profile with time.

- The digital controllers allow a programmed function which is stored in non-volatile memory.

- Programs consist of functions and associated settings called segments.

- These segments can be assembled into a program in a fixed format, such as a succession of ramp/dwell pairs (Figure 2).

- Segments include: Ramp: The setpoint temperature increases or decreases at a linear ramping rate until a specified target level is reached.

- Step: A step is a specialized type of ramp segment where the setpoint jumps to the specified target level.

- It is used when the most rapid change in measured value, limited by the heating elements, is desired.

- Dwell: The length of time required at a target temperature.

Communications

- Bi-directional digital communications via an RS-232 port is an option with select digital controllers.

- Eurotherm Controls has available a free demonstration program called the Communications Sampler.

- This program enables Windows to communicate with a single controller.

- The controller's parameters can be displayed on the screen and the value of the parameters can be changed with the computer keyboard.

- Two off-the-shelf software packages, Eurotherm’s iTools and SpecView allow the user to supervise groups of controllers, as well as retrieve data for logging and trend plots.

Holdback

- If the measured value lags behind the setpoint by a preset amount during ramp or dwell, the holdback feature can be used to freeze the program at its current state.

- The program will resume when the error comes within the holdback value.

Gain Scheduling

- Gain scheduling is the automatic transfer of control between two sets of PID values.

- Select digital controllers do this at a preset measured temperature.

- Gain scheduling is used for difficult to control processes which show large changes in their response time or sensitivity at high or low temperatures.